Safety and Risk in Electrical Low-Voltage Installations, Part 2

July 13, 2018

By Alfred Mörx

Taking adequate measures when planning and making equipment (e.g., low‐voltage switchgear assemblies) ensures that any risk that remains after the application of protective measures is as low as possible. Part 1 explored the relationship between risk and safety, seven reasons for implementing safety precautions, consequential damage, and its costs. Here in Part 2 of 3: consequential damage and its costs.

System protection and consequential damages

Installation‐specific consequential damages can be detected with the help of the damage interruption function. Recovery costs, e.g., of the low‐voltage switchgear assemblies and damaged system parts, must always be added.

The damage interruption function, also referred to as customer damage function, can be defined as the functional connection between the emerging damage in an electrical installation during failure of the installation(or during its restricted operation) and the duration of interruption.

The function can show points of discontinuity if damage to the means of production occurs when a specific value of the duration of interruption is exceeded. A good example would be preparations (e.g., food) which can no longer be further processed after a specific duration of process interruption and must be thrown away.

Detecting system‐specific damage interruption function

Consequential damages in the case of power failure can only be ascertained system‐specifically with sufficient accuracy because of the major differences in the use of the installations.

Additionally, knowledge of the consequential damages, as expressed through the damage interruption function, is also important for the interpretation of possible necessary backup power energy distribution systems. Also these backup power energy distribution systems with their switchgear assemblies and the switchgear built in them must in many cases meet higher requirements than the minimum requirements stipulated in the generally accepted technical standards.

For the detection of specific system‐specific Damage Interruption Functions from Damage Interruption Functions of more or less similar supply interruptions, detailed calculation concepts are available today (see [5] and therein cited literature).

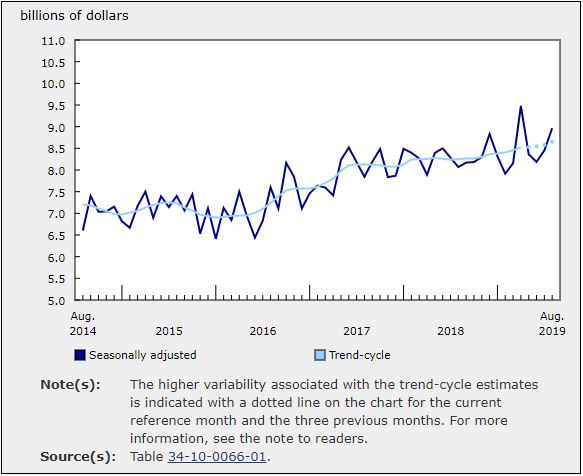

Already on the basis of the incomplete overview provided in the chart below, consequential damages, upon using the respective company‐specific data, can be calculated for a specific electric system and compared with the costs for any additional constructive measures for the installation of the system.

To calculate the total damage (e.g., after a complete or partial destruction of low‐voltage switchgear assemblies or system parts), add recovery costs (e.g., of the low‐voltage switchgear assemblies and damaged system parts).

Examples from the area of supply of information technological equipment

Low‐voltage switchgear assemblies that support IT equipment, that support business processes or such that manage the business process must always be carefully considered regarding their failure safety. In many cases, “only standard‐compliant switchgear” is not enough.

System failures in this type of plant can cause considerable consequential damage, even when the period of interruption is only a few hours.

In [07], the following information can be found for IT equipment (already in 2007!):

“The costs for lost working time as result from hourly rate and number of concerned employees can always provide a very rough idea because other factors are usually more important:

- possibly, contractual penalties for untimely deliveries are to be paid, which is common practice in the automotive industry today

- direct downtime costs also include any damage through loss of reputation that is difficult to quantify, like angry customers and suppliers

The more business processes depend on IT, the more seldom it will be that the consequences of IT system downtime are minor. For instance, 10 years ago you could at least still phone. Today, telephone exchanges are also integrated into IT today; at the same time, with e‐mail, part of communication has shifted directly to IT.”

A rough evaluation of the costs for the non‐usability of IT equipment for a few branches is summarized below.

[PLEASE INSERT EIN-20-Safety-1.jpg HERE]

Consequential damages per hour in the case of downtime of IT equipment; taken from Lenz, Ulrich; IT‐Systeme: Ausfallsicherheit im Kostenvergleich; 2007; www.cio.de/a/it‐systeme‐ausfallsicherheit‐im‐kostenvergleich,458076

A survey conducted in 2010, in which 182 people from small or mid‐sized retail and trade businesses participated, produced the results identified in the table below. Participants were asked how high they would evaluate operational damage in the case of total IT failure, depending on the duration of the failure.

In the case of a failure up to four hours, 50.3% of those surveyed estimated the damage to be between € 1000 and € 4999; 11.5% of those surveyed estimated the damage to an amount above € 19,999. For a failure of up to a week, 35.7% of those surveyed also estimated the damage to be above € 19,999.

[PLEASE INSERT EIN-20-Safety-2.jpg HERE]

Results of a survey of small and mid‐sized businesses (SMEs) and trade; taken from a study by ECC, NEG

Federal Ministry of Economics and Technology, Germany; Source: Statista GmbH, Statista GmbH, Johannes‐Brahms‐Platz 1, 20355 Hamburg, http://de.statista.com/; 2015.

Action planning

For a specific plan of actions that goes beyond minimum legal requirements for reducing the residual risk in low‐voltage switchgear assemblies, it is necessary to answer a key question: How great is the importance/significance of the low‐voltage switchgear assembly for the maintenance of operations and safety of employees working next to the switchgear assemblies (see Section 3)?

Responding to the following questions may help provide an answer to the above question.

- What are the technical impacts of a failure of a switchgear assembly?

- How high are the consequential damages; what does the damage interruption function look like?

- What are the possible effects of a failure of the switchgear assembly on the employees ensuring servicing? How are the preventative maintenance measures performed regularly to prevent failures and keep operating equipment in proper condition and servicing (e.g., repair, replacement of defective parts) carried out in practice?

- How great is the damage to the company’s image if delivery times cannot be kept? 5. What are the consequences of a switchgear assembly failure on the environment?

In Part 3: what’s involved in meeting employer responsibilities under workplace health and safety legislation, and six causes of arc faults in low‐voltage switchgear assemblies.

Alfred Mörx is the owner of diam‐consult, a consulting engineering office for physics focusing on risk analysis and protective technology in complex technical systems, since 2001. He studied technical physics at the Vienna University of Technology. As an expert for basic electrotechnical safety matters, he has been working in national, European, and international teams in the area of safe electricity application for more than 25 years; www.diamcons.com; am@diamcons.com. This article was previously published as an Eaton white paper

Read Part 1: http://www.electricalindustry.ca/latest-news/4202-safety-and-risk-in-electrical-low-voltage-installations-part-1